Overview: The 381

You COULD say that the 381 was the last Rickenbacker designed by Roger Rossmeisl, even if it didn’t get made until six years after he left. But that’s not exactly right—Rossmeisl never built a guitar exactly like the 381 we first saw in 1968. All the design elements trace back to Rossmeisl, sure, but they’re put together in a way Rossmeisl never actually did. So what do we call it? “Inspired by”? A pastiche? And WHO actually pulled all those elements together?

Well, Rickenbacker didn’t really have an in-house designer per se at the time. But they did have shop manager Dick Burke. Burke would later explain it like this:

“Things were slow at the factory so I wanted to come up with something new, something different. I’d always liked the carved tops, so we decided we’d try it.”

So is the genesis of what is largely regarded as Rickenbacker’s most deluxe guitar really that simple? Well, yes…and no. Let’s break it down.

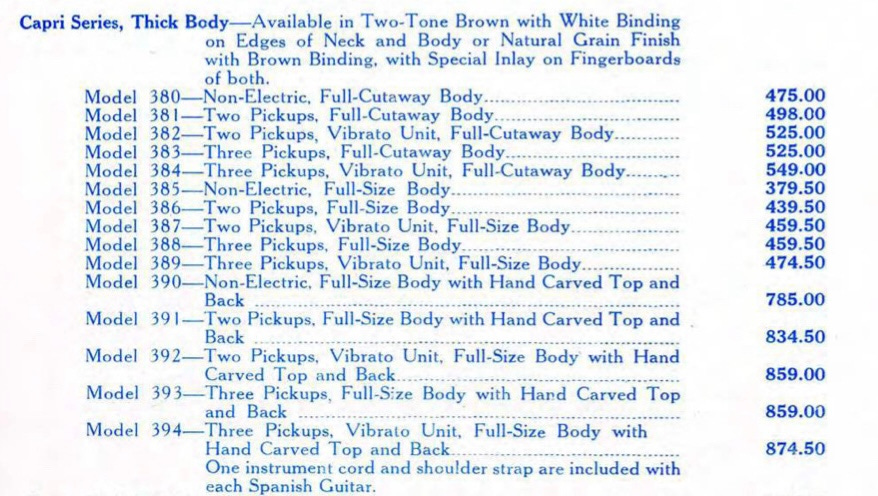

Now to be technical, Rossmeisl DID make a “381” in 1957. He made a couple, in fact. When you look at the 1957 price list, there are a LOT of guitars that never actually got made on there. “Vaporware” (click to learn more), one might say in the modern vernacular.

Given that these guitars are grouped under the category of “Capri Series, Full Body”, it will probably come as no surprise to learn that the first 381 prototype is basically a 360 Capri with a thick 3 3/16” body.

Nothing at all like Dick Burke’s 1968 version! But the second 381 prototype? That’s starting to look more familiar.

While at first this may appear to just be another “fat 360 Capri”, a closer examination reveals two key details. First, instead of a slash soundhole we have a traditional f-hole. But the second is far more pertinent—look closely at the reflections and you’ll see the top has a German carve.

Now you can get all the details on the German carve here, but here’s the Cliff’s Notes: it’s a dramatic, scooped edge contour that gives the guitar a sculpted, almost architectural presence. Like so:

The style originated with German violin makers and was popularized on electric guitars by…German luthier, Roger Rossmeisl. Thus the name

So now let’s jump ahead to 1968. With the factory slow and Burke looking for something new, Rossmeisl’s earlier German carved experiments drew Burke’s attention. And so 1968 became the year of the German carve.

There are two guitars from 1968 that are often referred to as “381 prototypes”. One obviously is, and the other….well, the lineage is less clear.

So here’s the one you might consider questionable. On the surface, it looks like nothing more than a 330 with a German-carved top and a flat back. Apart from the smaller pickguard—which was unavoidable—it IS a 330.

Except it isn’t. Let’s look a little closer:

Compare which fret intersects the body on each. Compare where the bridges are in relationship to the bottom of the slash soundhole. Thanks to the German carve, the neck had to join at a slightly different point to keep the neck pickup in the same relative position—causing everything to be shifted down about an inch.

So not “just” a 330 with a German carve, then. By Burke’s own account, it represents an early 381 experiment—even if it wasn’t the version he ultimately liked.

“I tried carving just the top, but I didn’t like it. It looks better done on both sides.”

-Dick Burke

Now the other one—with carving on both sides!—very clearly presaged the final product.

There are a couple of differences from the final product we can easily spot. One obvious thing is the headstock is bound—another 1968 theme as we’ll see in a minute. The other is the German carve itself—not nearly as dramatic and with a much larger edge around the outline of the guitar. Still, as first drafts go it’s remarkably close.

Taken together, those differences make the lineage clear: the 381 is best understood not as a Rossmeisl design, but as a Burke-era synthesis of Rossmeisl ideas.

But the 381 wouldn’t be the Rickenbacker with a bound headstock and a German carve that would go into production in 1968. That honor would fall to the niche 6006 Banjoline.

If we think of the 381 as a “360 Old Style with a German carve”, the 6006 Banjoline was a “360 New Style with a German carve”—although the body was of slightly different dimensions than a 360 and featured a flat back instead of the 381’s German carve. While it may have come first, it wouldn’t have much staying power—1968 was the only year of production. But keep an eye on that basic body style—we’ll see it again in just a moment.

The first “production” 381s were built in January 1969. But “production” may be overstating the case, as a handful of details were still in flux. In practice, those January guitars sit somewhere between prototype and production model.

Some differences are subtle, others more obvious—but taken together they show that the 381 was still being finalized on the shop floor. To understand what ultimately defined a true production 381, it’s worth looking at where the January guitars differed from the 1968 prototype—and where later 1969 instruments differed from that January batch.

At first glance, it’s likely that nothing obvious jumps out at you. This looks very much like the modern 381V69. But here’s where it differs from the 1968 prototype.

The headstock binding is gone. The German carve is much more dramatic. And critically, the body itself is much thicker.

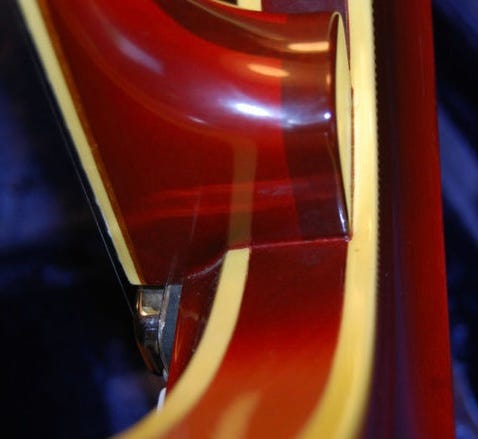

Let me explain what you’re seeing here. The photo shows the treble cutaway of the 1968 prototype positioned directly in front of the bass cutaway of a January, 1969 example. The difference is immediately apparent: the 1968 example is at least a quarter inch thinner even without counting the carves. In total, it’s thinner than a 330!

But even these January 1969 guitars aren’t quite the final product. There are two major differences between the January guitars and what would become the final production specs.

The pickup story is the first place where the January 1969 guitars sit awkwardly between prototype and production. The 1968 prototypes were fitted with toaster-top pickups, as were the January 1969 instruments. But in February 1969, Rickenbacker introduced a new, hotter pickup design specifically for the 381—referred to at the time as the “381 coil.” These pickups, commonly referred to today as “transitional” or “first-gen” Higains, first began appearing in February. The next full production batch in May saw these early Higains completely replace toasters on the 381.

Sticking with this “bridge from prototype to production” theme, we have to return to the topic of body thickness. Because while the new pickups would first arrive in February, 1969, the thick body would last until July.

First, compare the thickness of the carves on the top and the back of a January 1969 example. Notice how much thicker the back is than the top. Combined, they put the guitar at a total thickness of just under three inches—about half an inch more than the final production specs. Much of that is in that back carve.

Now, courtesy of Collin Whitley, here’s a February, 1969 guitar and a 1970 guitar side by side:

Despite the “edges” of the two being the same, notice just how much thicker both the top and bottom carves are on the earlier guitar. You can also see the difference in this three quarter view of the two:

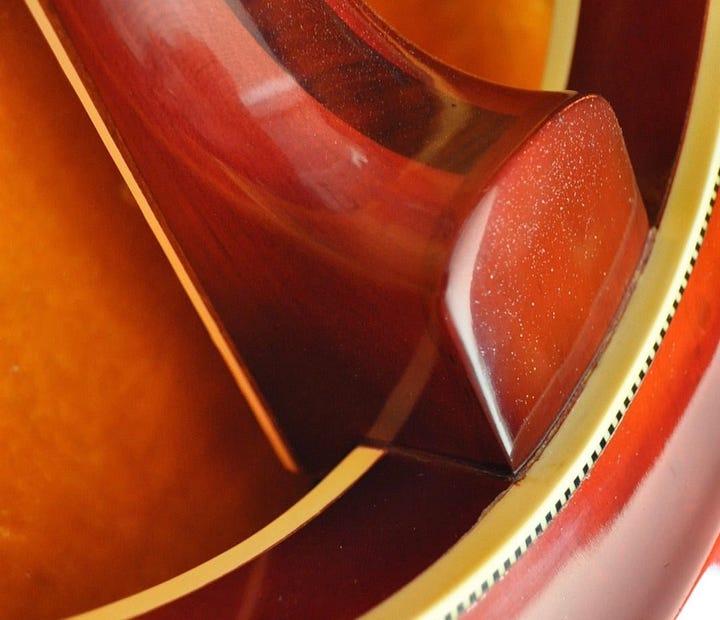

Another and easier to spot indicator of these early “thick back” 381s is the heel cap, which is itself much thicker on the earlier guitars.

The back became much shallower in July, 1969, bringing the guitar to its final production thickness of two and a half inches. And with that change, the 381’s final specs were set.

But before we put the prototypes and early production aside, remember how I told you to keep an eye on the 6006 Banjoline’s “360 with a German carve” body? Well, here’s why:

What we see here is quite clearly a 360 with a German carved top. At least two of these striking oddballs were made in February, 1969. The one pictured above featured a headstock with checkered binding, an “R” tailpiece, toasters, and an unfinished ebony fretboard. The other one differed in a few ways:

It had an Accent vibrato (click to learn more) tailpiece and the then brand-new “381 coil” pickup, introduced that same month.

These guitars and their silhouette in particular proved to be only a detour on the road to the production 381, but they serve as an important reminder of the 381’s ongoing, on-the-fly development process.

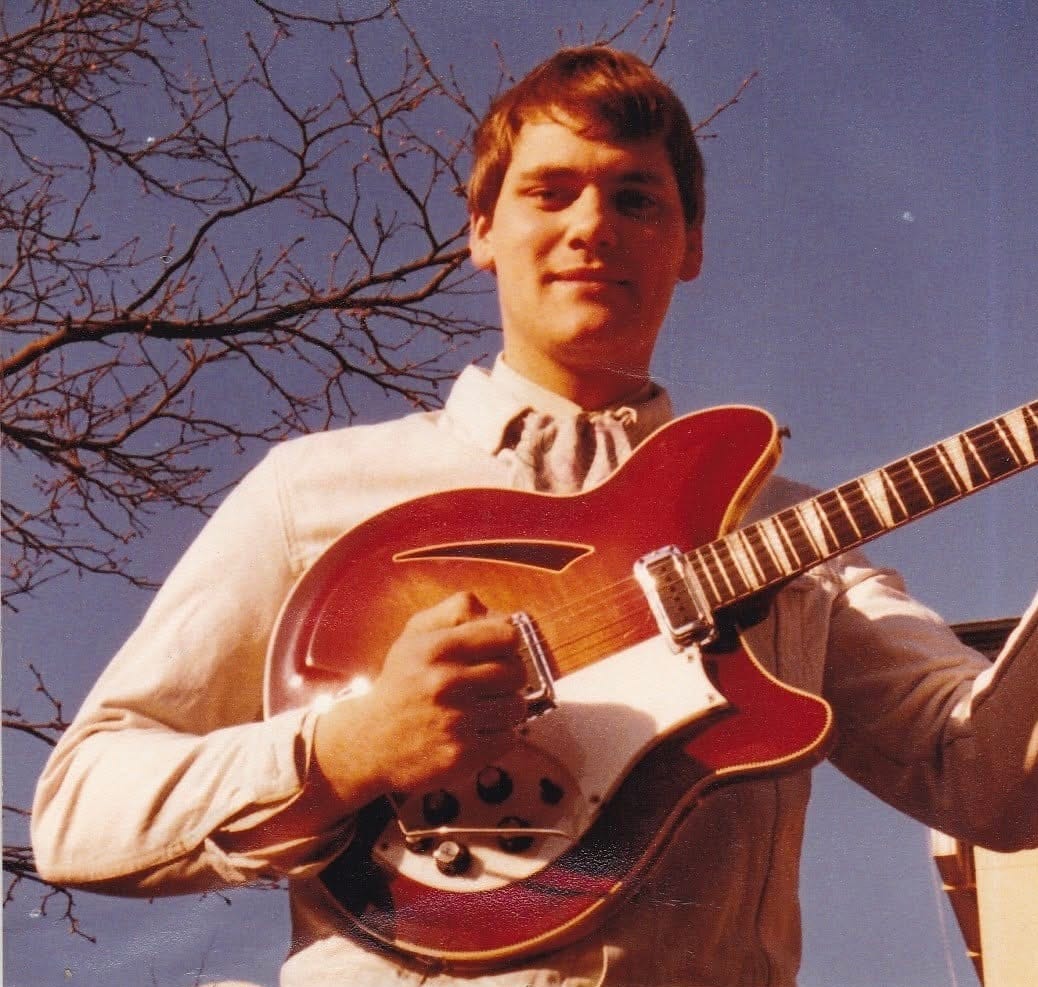

Even though production specs were set by mid 1969, a few outliers would appear over the 381’s production life. While the later 381V69 would be made in almost equal numbers in six and twelve strings, only one or two twelve string 381s were made during the guitar’s original production run. One of these could be seen being played in period by “The New Establishment”, Disneyland’s in-house pop band (seen here below with Rickenbacker Transonic amps—but sadly not the 381/12).

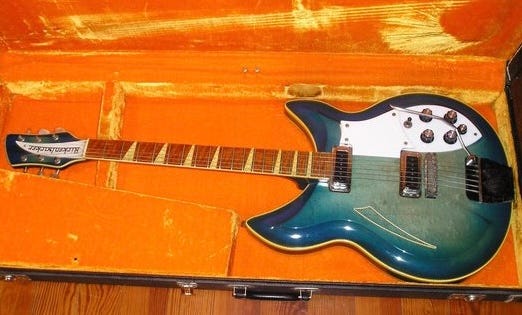

The other unique guitar of note was a one-off Blueburst model produced in 1972. The guitar had a number of unusual features apart from the custom color:

It has a bound headstock, Van Ghent tuners (click to learn more), one of the very last original Accent vibratos…and then there’s the soundhole. Or lack thereof!

The 381’s original run ended not with a bang, but a whimper. Never a huge seller, never attached to a marquee player, it was labor intensive at a time when factory staffing was low and bass demand was surging. While it would linger on the price list through 1975, the last known “original” 381 would be produced in 1973.

Oddly, despite how objectively “fancy” the 381 was, it was never positioned as a “flagship” model during its original run. That would change in 1987 when it returned as a vintage reissue—the 381V69—explicitly framed as the “top-of-the-line” model. The following year it would be joined by a 12-string sibling, the 381/12V69—which had its own “top-of-the-line” feature: a brand new 12-saddle adjustable bridge.

There were three immediately visible differences between the 1987 version and the original guitars—one technical and two cosmetic. On the technical front, the 381V69 featured the toaster pickups consumers expected on a “vintage reissue” guitar—ironic given that the original 381 had served as the Higain’s coming out party. That said, the pickups were the period “12k/hot toasters” which had a much higher output than vintage toasters.

On the cosmetic front, the use of highly figured birds-eye or quilted maple underscored the guitar’s premium positioning. The pricing made that intention explicit: where the original 381 carried roughly a twenty percent premium over the deluxe 360, the 381V69 commanded nearly forty percent.

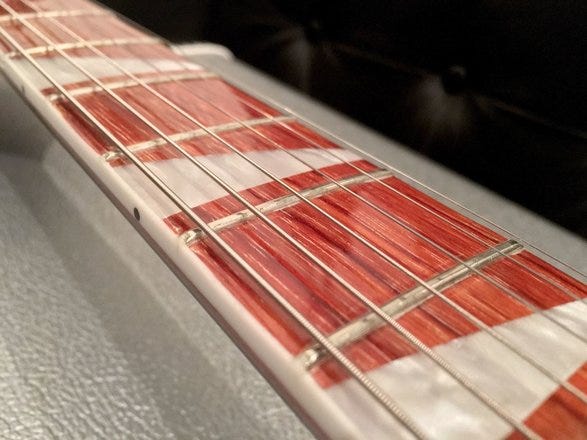

The other cosmetic change was a product of the period: the crushed pearl triangle inlays found on vintage era deluxe guitars had been discontinued in 1973 when their source dried up. The 381V69 therefore came equipped with era-standard poured pearlescent resin triangle inlays—although theirs were full width as opposed to the inset inlays found on main-line period guitars.

There’s also one difference you can’t see: the 381V69 featured modern integrated internal bracing as opposed to the original’s vintage-style x-bracing (click to learn more).

Changes over the 381V69’s life were few, and largely dictated by brand-wide evolutions.

In mid 1999 Rickenbacker replaced the “hot/12k” toasters with much more accurate “scatterwound” toasters, wound to around 7.5k ohm like vintage toasters. These can be easily identified by the corner screws, which switched from Phillips head to slotted as found on vintage pickups.

In early 2009 the triangle inlays would change from poured resin to laser-cut acrylic.

Beginning in 2005, headstock slots for the “sideways” tuners on non–vintage reissue 12-string guitars were extended all the way through the headstock for the first time. That feature reached the 381/12V69 in early 2010, but proved short-lived; by 2012, the headstock slots had reverted to the non-through style.

There is much debate (and no small amount of misinformation) about the wood Rickenbacker has used for their fingerboards. While the company has long used the generic term “rosewood”, the actual genus and species used have changed over time. As a result, “bubinga” or “African rosewood” are the terms most often applied to the evenly colored, tightly grained, fairly porous and slightly reddish boards historically used.

In late 2011 that changed to chechen, a Caribbean rosewood. Chechen is browner, has more color variation, a more charactered grain, and is less porous, meaning there is much less white grain fill used on the boards—that grain fill being a defining part of the Rickenbacker board “look” in many people’s eyes. This change would make it to the 381V69 around October, 2012.

In 2020, whether by conscious decision or a COVID-era supply chain disruption that ultimately stuck, the silver topped knobs that had been standard on all core Rickenbacker models since 1965 began to phase out across the entire line. By the mid 2021 black “vintage” knobs became standard on all models, including the 381V69.

While the changes to the 381V69 were minimal over its lifespan, the guitar would be used as a foundation for 1989’s John Kay 381JK Signature Limited Edition (click to learn more). Kay had briefly played a 381 in Steppenwolf’s prime, and the 381JK was built to his specifications featuring custom cosmetics and a very complicated electronics package. 250 were produced between 1989 and 1995.

The 381V69 plugged along at one-to-two production batches per year for most of its run, but sales began slowly declining over the last ten years or so of its life—still at a sustainable level, but just barely so. This combined with, once again, its labor-intensive nature led to a quiet discontinuation in late 2021. It may not even have been a conscious decision—the October, 2021 production batch just became its last. Because of Rickenbacker’s irregular, batch-based manufacturing process, the change went unnoticed by most until the guitar appeared on the company’s website as a “legacy” model in 2023.

A number of one-offs have been produced by the factory since—and been eagerly snapped up at extremely high prices. Proving there was nothing inherently wrong with the model…but that in the long run the limited demand for a super-premium guitar just didn’t justify the effort involved to continuously offer one.

In sum, the “problem” with the 381 wasn’t design, demand, or even desirability. It was a problem of process. Born not from a drafting table but from the shop floor, it represented a specific moment in time when Rickenbacker allowed experimentation, craft, and excess labor to coalesce into a single instrument. That same quality—what makes the 381 so compelling today—also made it perpetually ill-suited to a factory increasingly optimized for efficiency and throughput.

Seen that way, the parallel endings of the original 381 and the later 381V69 feel less like a coincidence than an inevitability. Both arrived during moments of transition. Both demanded more than the factory could—or would—give for long. And both ultimately disappeared not because they failed, but because they no longer fit.

Just like the original 381, the 381V69 died not with a bang but a whimper.

Want to learn more about…everything else? Check out our handy site map to see what we’ve already covered! Don’t see what you’re looking for? Drop it in the comments and we’ll add it to the queue!

Great article, Andy!😀

I have a 381 MG 6 string from 2015 and #5 of the JK models. Outstanding instruments !