Timeline: The Evolution of the 330

When somebody ask you “what should my first Rickenbacker be?” the answer is always “a 330”. It’s got the look, it’s got the sound, there’s always plenty of them available, and it won’t break the bank. It’s the total package. Who could have guessed that would be the case way back in May of 1961 when a few slight tweaks to the semi-hollowbody Capri guitars—a thinner body, a lower waist, and bigger horns—gave birth to the 330 shape we know and love to this day.

But the 330’s story begins in 1958 with the introduction of the brand new semi-hollowbody Capri line. And to tell the story of how we got from there to here we’ll actually discuss four models that were all built on the same foundation: the two pickup 330, the “330 with a vibrato” 335, the “330 with a third pickup” 340, and the “330 with a third pickup and a vibrato” 345. Apart from the number of pickups and the presence or absence of a vibrato, all four of these models are the same underneath.

Funnily, as ubiquitous as the 330 is today, for much of its life it was an “also-ran” sales-wise compared to its “Deluxe” 360 big brother. Up until the mid 1980s 330s are much rarer than 360s of a similar vintage. During the 1970s, in fact, it is difficult to pin down exactly when changes occurred as there are so few examples out there to use as a reference. So there are times here we will have to extrapolate and use 360s as well to try and pinpoint changes

And as we discuss changes, bear in mind that prior to the introduction of CNC manufacturing in 1995 these were handmade instruments, with tooling that wore down over time and was replaced with tooling that didn’t necessarily exactly replicate what it was replacing. The point being is that body/neck/headstock shapes continuously vary slightly over time. We’re not going to try and capture that here—it would just be impossible. We’re going to focus instead on significant or easily identifiable changes. Make sense?

One quick warning: I’m pretty sure this is the longest article I’ve written here. It’s long, y’all. So buckle up and let’s go!

1958

The full size Capri models introduced in 1958—Capri being the name of F.C. Hall’s family cat—were the product of an evolution that traces all the way back to Rickenbacker’s first “modern” electric guitars, the 1954 Combo 600 and 800.

Originally designed by industrial designer Hunt Lewis, the newly-hired Roger Rossmeisl added his own flourishes to the original drawings by slightly reshaping the treble cutaway and adding a German carve to the top. And then in 1957 Rossmeisl significantly modified the bass cutaway to create the Combo 850.

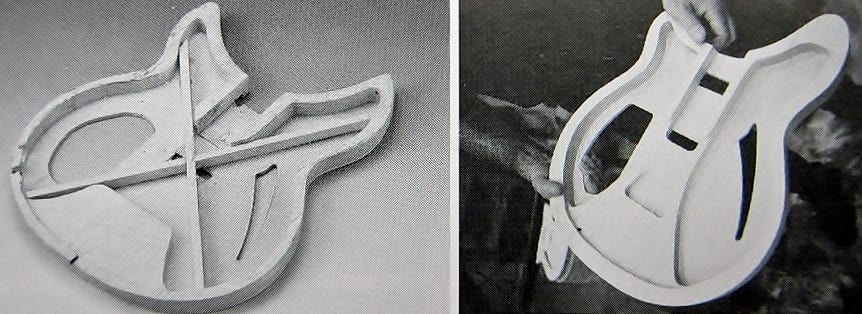

Still tinkering, Rossmeisl then took this basic shape—which was a solidbody—and hollowed it out by carving it out from the back and added a short scale neck to create the first semi-hollow Rickenbacker, the so-called “Polynesian” (from a local band F.C. Hall loaned the guitar to for feedback) prototype.

Realizing the German carve would be difficult/expensive for large scale production—remember, these were still hand-carved by Rossmeisl—the top was flattened, and so was born the semi-hollow body short scale Capri.

But we’re not done yet! Rossmeisl then built a handful of short scale Capris with a longer body—but still the short scale neck:

He then added a regular scale neck to this body:

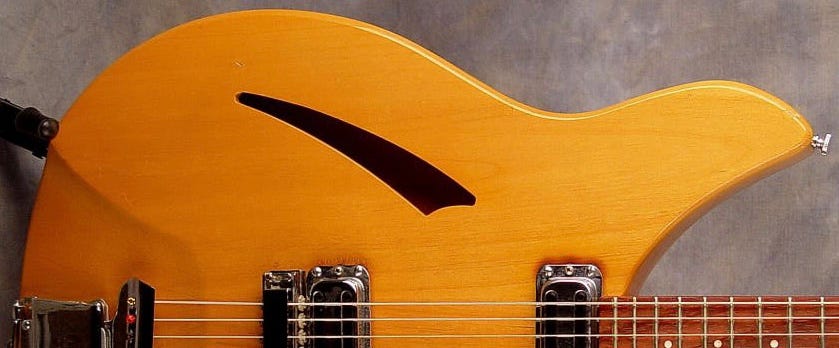

The long body was then widened, and a “cat’s eye/slash” soundhole was added (one of the first long body prototypes actually had a painted-on cat’s eye soundhole!). The full size Capri had arrived!

The following photo from Graham Griffith’s collection shows the long body 345 alongside three other very early full size Capris.

The full-sized Capri line of semi-hollowbodied guitars debuted with a total of 8 models split evenly between “Deluxe” 360 models and standard 330 models. While the 330 guitars lacked the binding and triangle inlays of the Deluxe models, the underlying foundation was identical: a 2” thick double cutaway back-carved semi-hollow body with a slash soundhole, two or three toaster pickups, and a set 21-fret neck. While that basic description would not change, many of the details would evolve over 1958 and into early 1959. Let’s run through some of them.

Several body materials/constructions were used before they standardized on a three piece maple body. Guitars can be found with bodies made of alder, birch, “butcher block” maple, mahogany, and two piece maple. Backs began as birch plywood before standardizing on solid two-piece maple.

The necks began as solid maple with maple headstock wings—as the short scale Capris would remain—before landing on the now familiar three piece sandwich—only they featured shedua instead of today’s walnut for the center stripe and headstock wings—consistent with Rossmeisl’s pre-Rickenbacker and prototype multi-piece neck designs.

As you can see above, both Kluson Deluxe and Grover Sta-Tite tuners could be found on early Capris, although they would eventually standardize on the Klusons in 1959. The headstock also featured a gold back-painted truss rod cover.

Early “standard” Capris featured the unusual dot markers found on earlier models, with two dots at the 5th and 17th frets, and three dots at the 12th. Later models would have the “normal” one dot/two at the 12th fret pattern we’re used to today.

Fingerboards were of paduak—despite being very similar in appearance, Rickenbacker’s “trademark” bubinga would not make an appearance for several years. These early boards also did not feature Rickenbacker’s now characteristic finished fretboards.

The soon-to-be “signature” Rickenbacker cat’s eye/slash soundhole went through (at least!) 3 basic iterations over the course of the year. Prototype and very early production models featured an extra-long soundhole of about 8 3/4” with a curved tail:

Version two would be shorter at 8 5/16” and without the curved tail:

And version three was just right at 6 1/8”:

Early non-vibrato guitars came equipped with a generic, “off the shelf” tailpiece. This would soon be replaced with the now familiar trapeze tailpiece.

Vibrato equipped 335s and 445s came with the extremely outdated Kauffman Vibrola (click to learn more)—which had first appeared in the 1930s!

Vibrato models came with roller saddles on a 6-saddle adjustable bridge. Non-vibrato models featured standard Rickenbacker 6-saddle adjustable bridges.

You’ll have noticed that many of the Capris we’ve looked at up this point feature a single level gold back-painted teardrop pickguard and a two control knob layout with one or two switches—with seemingly different control locations on each!

If you want to go down an inconclusive rabbit hole, try looking up what those early harnesses actually do! Suffice it to say that by the end of the year the guitar had received an upper guard for player comfort, and a more familiar four knob/one switch layout. We should also point out that the earliest guitars had chrome metal lap steel knobs, but those transitioned fairly quickly to the brown Rogan “cooker” knobs.

The guitar above is more or less the “final version” of the Capri, with its three piece maple top, short slash F-hole, three piece neck, and two level pickguard with four Rogan knobs/one switch controls—although this guitar still has Grover Sta-Tite tuners.

1959

In 1959 tuners finally standardized to Kluson “single line” Deluxes with small hex bushings.

But there was a quite significant change towards the end of the year: Rickenbacker changed from a nitro finish to a conversion varnish. With this change, fretboards gained their now-customary finish.

And while the template was more or less set, that doesn’t mean there weren’t still a few oddities out there, like this mahogany-bodied 345.

1959 also saw the birth of “Fireglow”, as seen above. Note also the change in the “burst” pattern that occurred in late 1958/early 1959: from that point forward “burst” guitars got a consistent rim around the face of the guitar whereas the entire carved tailpiece ramp was painted dark on earlier 1958 guitars.

Towards the end of the year, the finicky Kauffman Vibrola on the 335 and 345 was replaced with the Accent vibrato, a design licensed from Paul D. Butts. The same design would be licensed a year or two later by Gibson and branded as the “Maestro Vibrola”. Note that at their launch the Accent wore a small rhomboid “Ac’cent by paul” plaque on the front.

The “long” Kauffman would continue to appear on some guitars into early 1960, when it was completely replaced by the Accent.

1961

Always a tinkerer, Roger Rossmeisl had one last major trick up his sleeve before his tenure at Rickenbacker came to an end. Halfway through 1961 Rossmeisl took the existing Capri body and enlarged the horns, lowered and pinched the waist slightly, and reduced the body depth from 2” to 1 1/2” to create the “New Capri” 300 series guitars. And thus, with only minor changes since, the 330 as we know it today was born.

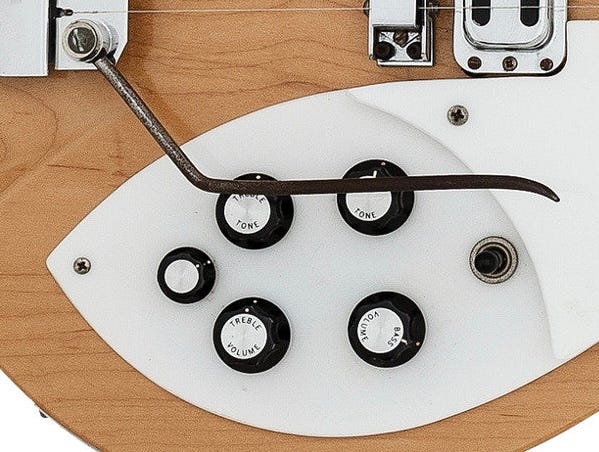

All hardware and plastics from the “old” Capri carried over—gold backpainted pickguard and truss rod cover, trapeze or Accent by Paul tailpiece, brown Rogan knobs—only with one extra control: the mysterious fifth “blend knob”.

I can’t begin to tell you how many times I have tried and failed to come up with an easy to understand explanation of what that knob does. The best I’ve come up with is that it controls the volume of the neck pickup relative to the bridge pickup and allows more precise fine tuning of the blend. I dunno. You do better.

A question that often gets asked is “at what point did the “New Capri” stop being a “New Capri”? That’s a great question. In fact, company literature never actually referred to them as “New Capris”—and indeed the Capri moniker was already gone on the 1960 price list—the “Capri” models were merely referred to as “310-375 Series, Thin Body.” Meaning that “New Capri” itself may well just be a collector’s term that’s been used so long we all just assume it’s legit.

The commonly accepted answer to the question—but by no means definitive—is “when the gold plastics go away.” That’s as good an answer as any—and about as authoritative!

1963

So by the “end of the New Capri?” definition we just provided, late 1963 was the end of the New Capri. This particular guitar killed it:

That guitar marked the end of the gold plastics era. White plastics had begun appearing on other guitars in 1961, and by the end of 1963 the “New Capris” were the last gold holdouts. But from this point on all the 330 and 360 models would have white plastics as well.

Along with the white plastics, black KK (Kurz Kasch) knobs would replace the brown Rogan cooker knobs. Also in late 1963 the Accent Vibrato would lose the small “Ac’cent by paul” plaque.

I should point out that 330s from the “New Capri” era are extremely rare, with only two currently documented. The vast majority of guitars from this era are deluxe 360 variants.

1964

1964 was a year of many changes for both the Rickenbacker line in general and the 330 in specific, despite almost none of the latter actually being produced. Well, kind of!

In case of “best timing ever”, after almost two years of back and forth before the deal was finally struck, Rickenbacker began producing guitars for UK distributor Rose Morris in January—just six months before George Harrison’s 360/12 would become a star on the silver screen and further link the brand to The Beatles. Among the six models selected by Rose Morris were the 335 and 345. Again, kind of.

See, Rose Morris had a couple of requests. The most significant was the soundhole—they weren’t crazy about the cat’s eye and wanted something more…traditional.

Rickenbacker designated these f-hole equipped guitars as the 335S and 345S (“S” for special), but they’re better known today by their Rose Morris model numbers—the 1997 and 1998.

Apart from the f-hole soundhole, the 1997 and 1998 were otherwise stock 335/345s, which is why we’re talking about them here. Does that mean we have to discuss the 1993? Is that a 330 at heart as well?

Well…the factory designation for the guitar was a 330S/12. So yes, technically it’s a 330. But look at it! It’s a 330 neck on a 360 body. That makes it…neither?

You may not realize it, but the 1993 was the first “production” 12-string Rickenbacker. Harrison’s 1963 360/12 (along with Mike Campbell 1963 625/12) were prototypes—and the handful of additional 12-strings built before the 1993’s first production run in July of 1964 were also handbuilt. As such, they were still “figuring things out” with the 1993. Nowhere is this more noticeable than on the truss rod cover:

The Rickenbacker’s novel headstock led to novel problems, like having the truss rod cover interfere with strings angling down to the sideways tuners. The so-called “stubby” truss rod covers on the first production run in July of 1964 were crudely hand shaped to eliminate this problem. The shaping would be refined by the next batch in November.

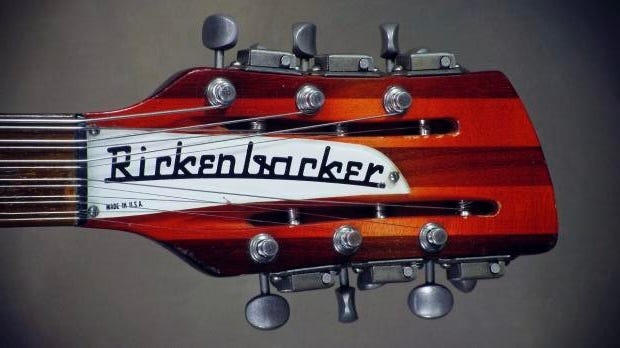

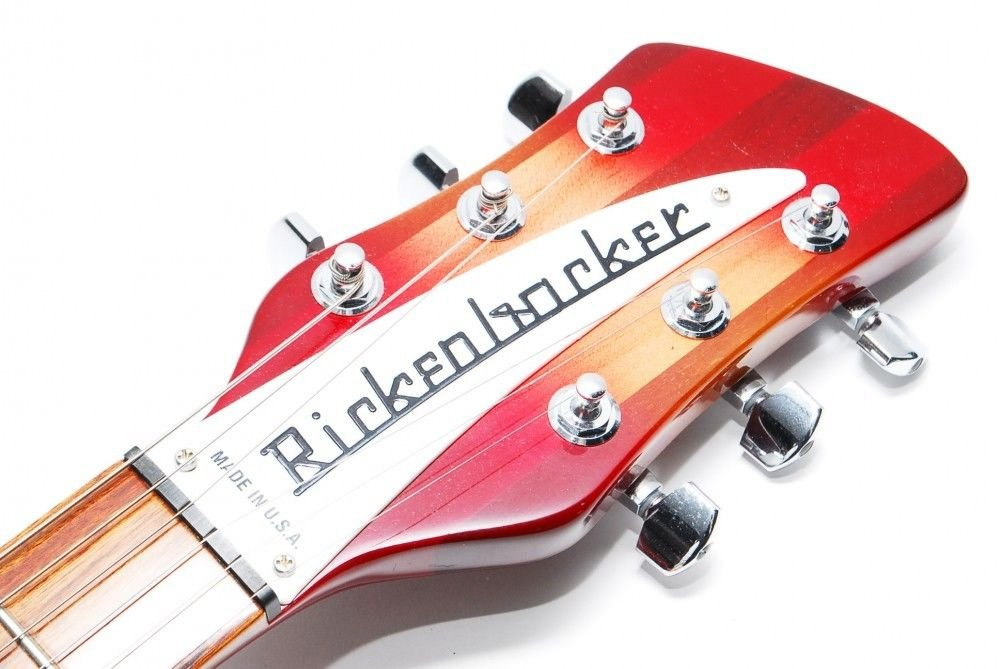

There were a number of other small changes to the 330 in 1964. One was another Rose Morris request: they asked for “MADE IN U.S.A.” to be added to the truss rod cover, which was rolled out across the entire product line.

Looking closely at the headstock you may notice a couple additional changes. Round tuner bushings replace the old hex bushings, signifying that the tuners themselves had changed from “single line” Kluson Deluxes to “double line” Kluson Deluxes.

And the headstock itself had changed shape—losing about 1/4” in width from the 1963 and earlier version—most noticeable in the thinner headstock wings.

The heel of the guitar also transitioned from square to rounded.

And midway through the year, the toaster pickup bobbins lost the injection molding “dimple marks” in the corners, becoming smooth all the way across the “toaster slots”.

It was also “around this time” that the fretboard material changed from paduak to bubinga. The transition to “vintage specifications” that began with the 1961 redesign was almost complete.

1965

1965 would bring the first “proper” 330/12s—and a fancy new tailpiece!

The “R” tailpiece came first, appearing in 1964 on the new “round top” 360, and replacing the old trapeze tailpiece on the 330/340 when domestic “slash soundhole”production restarted in 1965. These early R tailpieces were chrome plated cast brass with hand cut (for 6 or 12 strings) retaining slots on the back, and were slightly larger than later tailpieces.

The 330 was actually the last “core” model to get a 12 string variant—if you don’t count the 1993 as a 330 WHICH I DON’T! It has binding, therefore it’s not a 330. It’s a 360 with a 330 neck, so there!

But in November the first production batch of the 330/12 was built. Apart from the extra strings and associated headstock, all other features were consistent with its 6-string brethren.

Except…the 330/12 was also the first 330 to feature the new silver top knobs that had first appeared on the new “round top” 360 in 1964. When those knobs had debuted they were unlabeled, but by the time they appeared on the 330/12 they had gained the now familiar BASS/TREBLE VOLUME/TONE labels, with a dash indicator on top.

There’s one oddity of note from 1965: a number of 330s were built with serial number stickers on the headstock rather than a stamped jackplate. Why these exist or when exactly they were made we have no idea.

1966

In late 1966 the chrome-plated brass “R” tailpiece would be replaced by a chrome-plated zinc alloy piece. The new tailpiece was slightly smaller and featured cast in string retainer slots instead of the brass version’s hand cut slots.

Around September the “final” version of the silver top knobs would start appearing across the entire line, with dots replacing the dashes on the top. They began appearing on the 330 in December, and in December you will find guitars with old knobs, new knobs, and mismatched knobs like the 335 below that has “old knobs” for the neck pickup and “new knobs” for the bridge pickup and blend knob.

Also in December the 330’s top changed from three pieces to two center-seamed pieces. To see it clearly look closely at the wood grain lines between the pickguard and the center seam in the picture below.

1967

The 6/12 string “convertible” 336/12 was introduced, along with the similarly equipped 366/12 and 456/12. When engaged, the comb you see below captures and pulls down the octave strings, muting them and “converting” the 12 string guitar to 6 strings.

On the semi-hollowbodied 330 and 360 with their top-mounted pickups, the converter assembly had to be raised up from the guitar face to “reach” the strings. A white plastic block made of the same material as—and integrated into—the pickguard was installed to meet this need. An extra bracing block was also added inside the guitar below this mechanism to reinforce the top.

Much can be said about the converter guitars, but in the end it was a novel idea of limited utility that did not last long in the marketplace. Production would end the following year.

In January—and only in January—a batch of Rose Morris guitars destined for Italy were a little unique.

If that guitar looks a little “off” to you, it is. Rickenbacker had built a new “round top” 360-based Rose Morris model with an f-hole in 1967–with a new template for cutting the f-holes. When they built this batch of guitars they used the new guitar’s template for the f-holes on the older 1997 and 1998, and…it ended up in a different place.

Higher, closer to the centerline, and more angled, the new f-holes just look…wrong. Rose Morris models made later in the year had the f-hole in the “right” place.

1968

Around mid-year, the MADE IN THE U.S.A. imprint on the backpainted plexi truss rod cover would begin moving from parallel to perpendicular to the Rickenbacker logo, by the nut. A handful of models—including the the 330 and the 335 (but not the 340 or 345) would also have their model number printed above the MADE IN U.S.A. marking.

The 336/12’s truss rod cover would not change to the perpendicular MADE IN U.S.A. version, and production of the model would end in August.

Towards the end of the year the nut changed from a black phenolic material to white.

1969

The last “non-reissue” Rose Morris spec guitars would be built mid year, and were shipped by Rose Morris to Rosetti in Italy. Despite being made for a UK distributor, UK customers could not buy these last Rose Morris guitars.

Just like the guitars from early 1967, the f-hole on these guitars was in the “wrong” place. These guitars would also represent the last “production batch” to feature the Accent Vibrato. While the 345 would remain on the price list until 1973 and the 335 would last until 1978(!), apart from a couple of special orders in 1970 neither would be mass produced again. The “-5” model vibrato era was over.

By late 1969 the 330 and 335 lost their “model name” imprint on the truss rod cover above the MADE IN U.S.A., along with all other models with this feature.

And finally, there’s an oddball prototype from 1969 we should probably talk about: the 340 “slanted fret”.

Not today’s fanned multi-scale fretboards, the idea here was that slanted frets more closely fit how a player’s fingers naturally fit on the fretboard and would make things like barre chords easier. Slant fret 360s would appear in late 1970 and price lists starting in 1971 would state that the option was available on “almost any model”. In practice, this prototype guitar is the only “non-360” slant fret model from the pre-481 era I’ve ever come across—apart from a slant fret 341 Lightshow custom built for Roger McGuinn.

1970-1971

1970-1971 was kind of the nadir of Rickenbacker sales. How bad was it? Well, down from a peak of over 100 employees in the plant to only 8 bad. Were it not for 4001 demand taking off in 1971-1972 and then absolutely exploding in 1973 we probably wouldn’t be talking about Rickenbacker today. But it did, and we are!

All that is to say we know a LOT happened in 1970 and 1971, but it’s hard to pin down exactly when given how few data points we have to work with. Here’s what we know: we ended 1969 with 21 frets and toaster pickups. By mid 1971 we had 24 frets and first gen threaded polepiece Higains. Kinda mostly.

See, unlike the 360 that more-or-less cleanly converted first 6-string and then 12-string guitars to 24 frets, the 330 didn’t really give up on 21-fret guitars just yet. You will find 21 fret 6-string 330s alongside the new 24 fret versions all the way to 1976. And the 330/12 wouldn’t make the jump to 24 frets at all until 1977!

But we know for a fact that the 24 fret 330 first appeared in this period, and we know that first gen Higains appeared around the same time. The exact order of each? Can’t say.

The first gen Higains first appeared on the 381 in 1969, and would begin replacing the toaster pickup on other guitars in 1970. Unlike the toaster’s magnetic polepieces, the Higain featured non magnetic polepieces made of threaded stock that rested on a bar magnet at the bottom of the pickup. They were designed to meet the market’s demand for a “higher gain” pickup—thus the name. The bobbin was made of clear or green PCB material that was painted black.

Secondly we have the 24 fret neck. Like the Higain pickup, it was an attempt to respond to the market’s demand for more “modern” guitars. By early 1971 the 330 6-string was mostly—but not completely!—converted to 24 frets.

In discussing 1970-1971 we have to briefly mention the 331 Light Show. That’s kinda a 330 variant, right? Kinda, I guess. But mostly it’s its own thing, and deserves its own writeup. It’s in the queue, and once it’s done I’ll come back and add a link here!

But we need to discuss it here because in 1971–and into 1972–the “standard” 330 got a “deluxe” feature: a bound fretboard. But only the 24 fret examples!

So why? You can thank the Light Show. They were making a boatload of those in 1971 and only a handful of 330s—and the Light Show had a bound fretboard. In manufacturing it’s almost always cheaper and easier to run a couple more of whatever you’re making than to change the line over to run a few of something else. That’s almost certainly what’s going on here.

And it’s just the fretboard, not the entire neck. The 331 had a one piece maple neck, and these bound neck 330s have a standard three piece neck.

1973

In mid 1973 the Higain would be refreshed. It would be wound a little bit hotter, and the threaded stock polepieces would be replaced by button-top drive screws that would be painted black along with the bobbin. These pickups would start appearing on the 330 in late 1973.

Late in the year the nut would revert from white to black phenolic.

1974

In May of 1973 a transition to the neck construction on the 360 began. While the neck would remain composed of 3 pieces, the center “stripe” would halve in size from 5/8” to 5/16”—similar to the skunk stripe that had first appeared on the 4001 in 1972. This process would make it to the 330 in 1974.

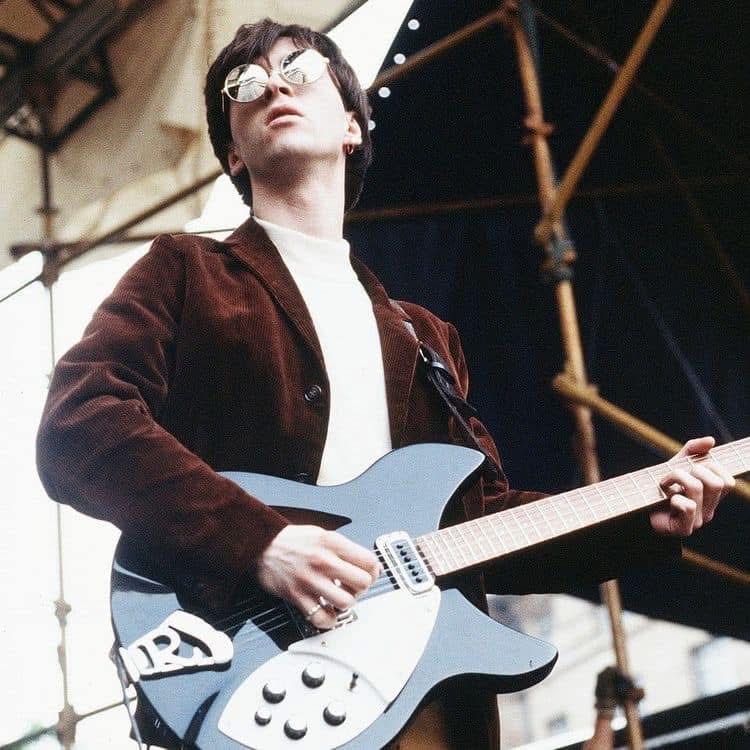

And while this is jumping ahead a bit, I will argue that four specific guitarists were critical in leading to Rickenbacker guitars’ resurgence in the 1980s. One (R.E.M.’s Peter Buck) favored a 360, one (Ton Petty) made 620s cool, but the other two were 330 players. The first was The Jam’s Paul Weller, who owned and played a number of 330s, chief among them a 21-fret 1974 model onto which Weller scratched “I am nobody”.

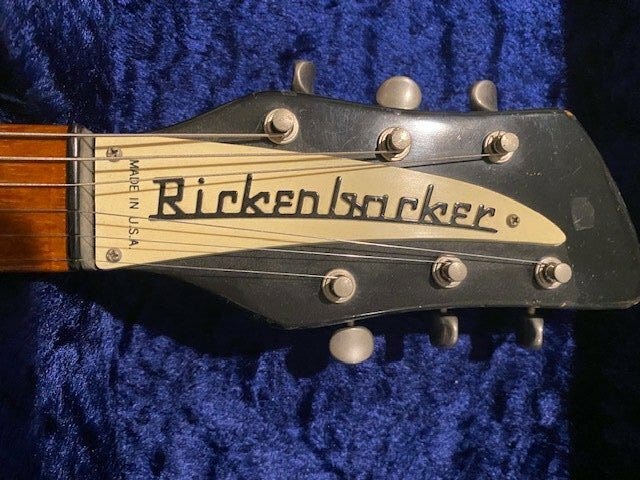

1976

Starting in late 1975, the old style backpainted plexi truss rod cover was replaced on all models by an injection molded cover with a raised logo. The logo would be painted (white for black TRCs, black for white TRCs), and MADE IN U.S.A. was stamped at the bottom by the nut. Higher volume guitars would also have their model number stamped below the MADE IN U.S.A. imprint. As strange as it may seem today, when the 330 got the new truss rod cover in early 1976 its volume did not “qualify” for the stamped model number.

I’m not saying there weren’t more, but the last documented 21 fret 330 was built in late 1976.

1977

1977 would be the year the 330/12 would finally make the jump to 24 frets.

1979

By 1979 demand for the 330 had grown enough for the model to “earn” its model number stamp on the truss rod cover.

1982

Things had not been going well for Kluson since the late 60’s. Competitors like Grover and Schaller and Gotoh had kept improving their products, and Kluson had not. By the early 1980s Rickenbacker was one of their largest remaining customers. And so when John Kluson died in late 1981 and no buyer expressed interest in the company, the decision was made by the family to close the doors. Which left Rickenbacker in a bit of a bind as the Kluson Deluxe was still their primary guitar tuner.

At the time, Grover made a guitar tuner of similar construction to the infamous “wavy Grover” bass tuner with a not dissimilar footprint to the Kluson—and similar “bean” tuner heads. And so the “Slimline” or “box Grovers” began appearing on “vintage headstock” guitars in mid 1982. From the front of the guitar, you can’t tell the difference. From the rear you absolutely can, as shown below. By the end of 1982 this was the primary tuner on all vintage headstocks, and it would be until mid 1984.

If you buy my argument that there were four artists primarily responsible for Rickenbacker’s 1980s resurgence, the second 330 slinger of note was The Smiths’ Johnny Marr, who owned a 1982 330 in Jetglo.

1984

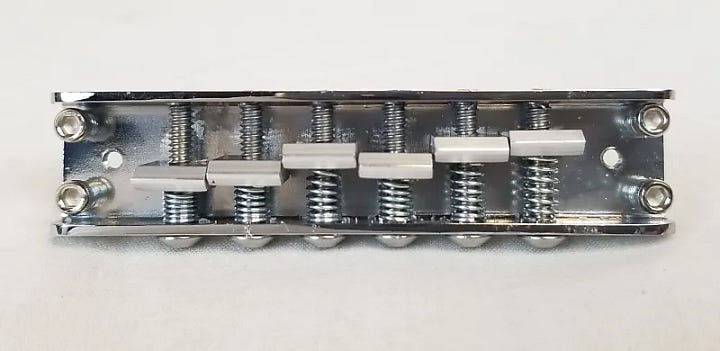

The first year of John Hall’s ownership was one of the most significant in company history. Four major changes (and maybe five?) impacted the entire Rickenbacker guitar line, including the 330, in 1984. First was an updated bridge design. The locking nut that had held the saddle adjustment screws in place since the bridge was developed in the 1950s was removed and replaced with a spring behind the saddle to achieve the same end. This slimmed down bridge would become the default on all models in January.

Secondly, the “guts” of the semi-hollow body guitars would change as the internal bracing would migrate from “x-bracing” to modern “integrated” bracing.

Thirdly, starting in late 1984/early 1985, like all guitars the 330 would transition from the traditional Rickenbacker double hairpin truss rods to a pair of conventional single action truss rods. Neck construction would change slightly to accommodate—but only internally in the truss rod channel. The only way to identify which truss rod system is in place is to remove the truss rod cover.

Additionally, in early 1984, the Grover Slimline tuners currently in use were discontinued by Grover. While Rickenbacker worked on a permanent solution, the Grover Rotomatics in use on the 360 were used in place of the Slimlines on 6-string 330s. The remaining Slimlines were reserved for 12-string guitars. It looks strange to see Grover Rotomatics on a vintage style headstock, but during this brief period it is 100% correct!

But this would lead to the fourth major change—the paddle headstock.

Notice how the Grover Rotomatic bushings just barely fit on the skinny Jetglo vintage headstock above? The same was true of the Schaller M6 tuners that would be their replacement. And so the headstock for all non-vintage/reissue guitars would be widened about 1/2” to make room—although the first few 330s to wear the paddle would still be equipped with Grover Rotomatics.

At some point during the year, the “vintage tone circuit” (a high pass filter capacitor) that had been standard on all Rickenbacker guitars and basses since the 1950s was removed, giving the bridge pickup a higher output with more bottom end.

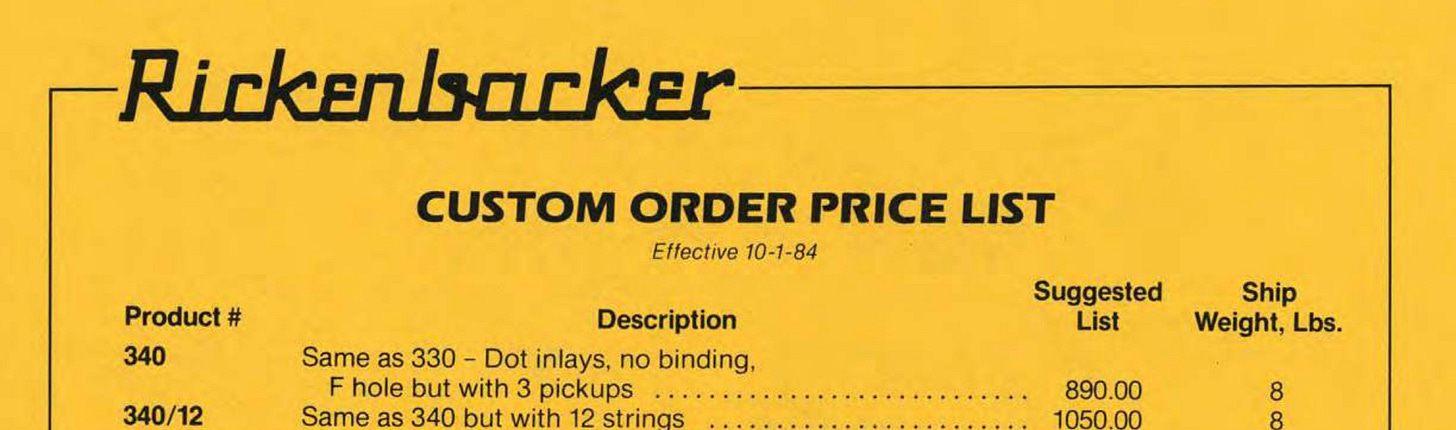

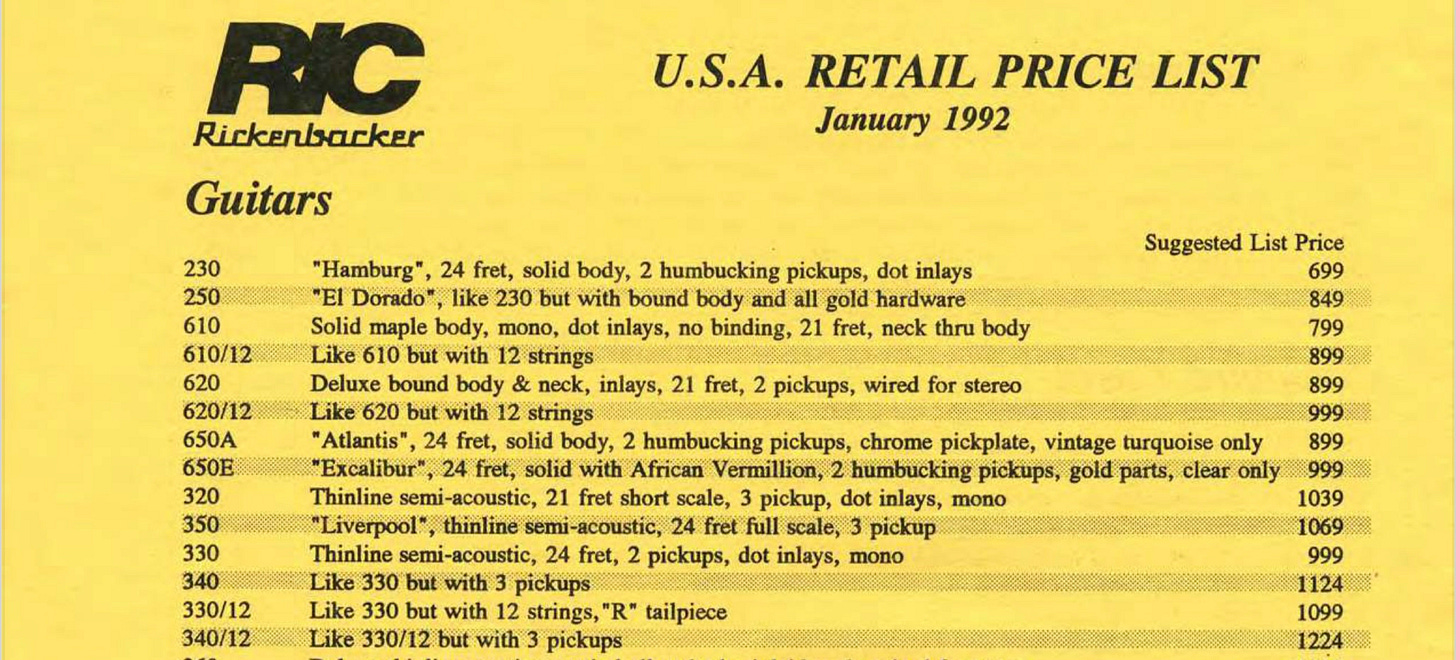

Towards the end of the year the 340 and 340/12 were moved off the “main” price list and onto the “custom order price list”, from whence it would disappear until the 340 and 340/12 would return to the “main” price list in 1992.

Finally—and do not quote me on this—there is the maybe? fifth major change of 1984. 1984 is “probably” the year the neck radius changed from the vintage 7.25” to 10”. We know that early 80s guitars have the old 7.25” radius, and I own a 1986 guitar with a 10” radius, so it makes sense that with everything else going on in 1984 that’s when the neck radius changes as well.

1985

Towards the end of 1984 all models, began losing the “model number” stamp on the truss rod cover. While the very last 1984 330s still had the model number truss rod cover, the very first 1985 330s did not. They did, however, have the model’s first Schaller M6 tuners.

Mid 1985 would mark the beginning of the BH/BT (black hardware/black trim) era, with Midnight Blue, Red, White, Silver, and Mapleglo guitars equipped as standard with black finished tuners/pickup covers/bridges/strap pins/serial number plate and black plastic binding/pickguard/truss rod cover.

1986

Two options were added to the pricelist list in 1986: the stock Higain pickups could be replaced with toasters (referred to as “Vintage Bar”), and the R tailpiece could be replaced by an Accent Vibrato (referred to as “Vintage RIC Vibrato”).

Guitars thusly equipped are referred to today as “VP” (vintage pickup) or “VB” (vibrato)—language that was added to the price list in 1996. An Accent equipped 330 is therefore a 330VB, not a “335”. Unlike in their original run, the Accent option did not include a roller bridge—the standard 6-saddle adjustable bridge was left unchanged on guitars with the Accent option selected.

While it would not appear on the price list until 1987, a reproduction 1997 would begin production in late 1986. Offered as both the 1997 and 1997VB, it utilized the same body and neck templates as the 360V64 and featured a 21-fret neck, square heel (technically incorrect), toaster pickups, a trapeze tailpiece or an Accent vibrato (for the 1997VB), Kluson-style tuners and a plexi truss rod cover on a small vintage style headstock, and an f-hole soundhole.

Tom Petty was given—and used extensively—one of the first 1997s built, customized for him with gold plastics and his name engraved on the upper guard.

The toaster pickups on the 1997 and 1997VB were the “hot/12K” toasters that had first appeared in 1982 on the B-Series guitars. They are much hotter than vintage toasters—and hotter still than period Higains. Hot toasters can easily be identified by the Philips head screws on the corners of the casing.

This one’s a little hard to pin down, but I’m gonna go with “early 1986”, although it could be “late 1985”. Since their introduction in 1973, the button top Higain pickup bobbins had been made of a greenish PCB material which—along with the button tops drive screw polepieces—were then painted black.

In 1986-ish, however, the bobbin material was changed to a black PCB material, eliminating the need for paint.

1987

The newly launched 1997 was used as the “foundation” for the first Limited Signature Edition guitar: the Pete Townshend 1998PT.

The 1998PT took the 1997, added a third pickup, a special pickguard, and an “R” tailpiece—disabling or replacing the original Rose Morris 1998’s Accent had been a signature Townshend move back in the day!

A “third pickup” option was added to the price list in 1987. When selected on the 330, the factory officially designated the finished guitar a 340–despite the “340” no longer appearing on the “custom order pricelist”. When selected on a 1997 the model was designated a 1997SPC, not a 1998. Who knows why?

1991

A minor change to all Higain equipped guitars—including the 330–occured around August. A new dual-use pickup bobbin was introduced for use on both Higain and toaster pickups—ending the “fiberboard” button-top Higain era.

1992

In 1992 the 340 and 340/12 would return from exile to the price list.

1995

Around July, all non-vintage/reissue guitars—including the 330–moved away from the vintage reeded edge strap button that had been used since the late 50s. It was replaced with a Schaller strap lock button, albeit still attached to the Rickenbacker style bolt instead of the “stock” wood screw. While the supplier has changed over the years, the style remains in use to this day. The reeded bolt is still used on vintage/reissue guitars, and as the mute adjustment screw on bass bridges.

Rickenbacker had begun moving to CNC manufacturing in early 1995. Prior to CNC machining, bodies and necks were hand cut using templates that wore over time, leading to slight variations from guitar to guitar and year to year as those templates wore and were replaced. Now the same shape would be cut every time.

The 330 would make the transition to CNC in October. It’s easy to spot the difference in the horns: the pre-CNC horns are rounded from years of tooling wear. But the CNC horns are sharp and pointy.

In late 1995 the Accent Vibrato equipped 1997VP would drop from the price list, but the three pickup 1997SPC would officially be added.

1996

In October we’d take a step back towards vintage specs. The three piece neck’s center walnut “stripe” would increase from 5/16” to 5/8”—back to its pre 1973 dimensions.

1999

In mid 1999 Rickenbacker replaced the “hot/12k” toasters with much more accurate “scatterwound” toasters, wound to around 7.5k ohm like vintage toasters. These too can be easily identified by the corner screws, which switched to slotted as found on vintage pickups. These began appearing on the 1997 and 1997SPC in August.

2001

In 2001 the 1997 and 1997SPC would be dropped from the price list. A number of one-offs and special dealer orders have been produced since, but it has not returned to the catalog.

2003

Here’s another minor Higain tweak. In March, shortly after “dimples” (to match the molding marks found on 63 and earlier toasters) were added to the corners of the slots on toaster bobbins to help make the new C series guitars appear more authentic, Higains got the dimples as well. These pickups first began appearing on the 330 mid-year.

2005

Over the course of the year, all non-vintage reissue 12-string models saw a significant headstock design change: the slots for the sideways tuners were cut all the way through the headstock to make stringing easier. The change would make to the 330/12 in September.

2006

In May 2005, for the first time in its history the Higain gained adjustable button top polepieces. These pickups would would first appear on the 330 in June of 2006. This version of the Higain is still in use today. Fun fact: you can remove those polepieces, screw them in from the back, and put it in a toaster case. No one will ever know!

2007

In April of 2007 we had another step back towards vintage specs. The paddle headstock shrank back to pre-paddle dimensions—why the Schaller tuners suddenly “worked” on the smaller size headstock? Who knows.

2008

At the end of 2007 the 340 and 340/12 were removed from the price list for good. A large number were produced in 2008 to clear the backlog, with the last 340/12 rolling off the line in October. Any three pickup 330 found after that point has PROBABLY had the middle pickup added aftermarket as Rickenbacker last offered the “add a third pickup” option in 1991.

2011

There is much debate (and misinformation) about the wood Rickenbacker has used for their fingerboards. While the company has always used the generic “rosewood” terminology, the specific genus and species used has changed over time. Consequently, “bubinga” or “African rosewood” are the terms most commonly used to describe the fairly evenly colored, tightly grained, fairly porous and slightly reddish boards historically used.

In late 2011 that changed to chechen, a Caribbean rosewood. Chechen is browner, has more color variation, a more charactered grain, and a less porous grain, meaning there is much less white grain fill used on the boards—that grain fill being a defining part of the Rickenbacker board “look” in many people’s eyes

2012

A very subtle change was made to the “MADE IN U.S.A.” font on all raised letter truss rod covers. The new font is a little “squarer” and more “compact”.

2014

What if 330 but walnut? That question was answered in 2014 with the launch of the 330W and the 330/12W.

Identical to the standard 330 in all ways but woods and finish, the new 330W featured an oil-rubbed walnut body and maple fingerboard

2020

Whether it was a conscious decision or a COVID supply chain issue that just became permanent, the silver topped knobs that had been standard on all core Rickenbacker models since 1965 began phasing out across the entire line. By the end of the year, black “vintage” knobs became standard on all models, including the 330.

2021

In July a monumental change took place: fingerboards went from being finished to unfinished on all core instruments, including the 330.

2023

January brought one of the most significant changes in years: a return to the vintage-spec 21-fret neck.

They clearly used existing “reissue” tooling, as it featured a square neck heel.

While not outwardly visible, because the same CNC body template as the 360/12C63 was used, the 330 gained the integral X-bracing utilized on the reissue guitars.

One “once you see it you can’t unsee it” detail of this new 21-fret version is the teardrop pickguard: the outer edge in the upper guard area is much “straighter” and less rounded than older 21-fret guitars’ pickguards.

In September 2022 Rickenbacker had quietly begun finishing fingerboards again, ending a brief and unsuccessful experiment. No 330s were built after September in 2022, but when the first 21-fret 330s were built in January of 2023 they featured finished boards.

And finally, early in the year the primary tuner manufacturer changed from Schaller to Gotoh. The new tuners were cosmetically identical the Schallers they replaced apart from the “R” logo on the back. The new tuners began appearing on the 330 in April.

2024

The twin single action truss rods for all non C-Series guitars were replaced by a single, dual action truss rod. The change can only be seen by removing the truss rod cover.

And that brings us up to date on Rickenbacker’s unsung hero of the line, the humble 330. I tried to be as complete and correct as possible, but know I missed something/got something wrong. Drop it in the comments and I’ll fix it!

As always, I have to thank folks like Ron O’Keefe and Graham Griffiths for documenting their collections and sharing them with us. Without their invaluable photos of early guitars, this sort of timeline wouldn’t be possible.

Want to learn more about…everything else? Check out the rickenbacker101 site map and see what’s already been covered! Have a suggestion about what we should tackle next? Drop it in the comments and we’ll add it to the queue.

Nicely done, Andy. In the 1961 sequence you show a photo of a 330 in the "New Capri" style. This particular guitar was one of the few (2 documented) 330-style guitars in the "New Capri" era - all the others 1961-1963 were double-bound 360-series models. https://www.ronsvintage.com/guitars/1961-rickenbacker-new-capri-extremely-rare-near-mint-330

Also, another fun fact - the "New Capri" 330 depicted sports the earliest example of the 5th blend knob (determined by SN).

Well done! As I was a Rickenbacker factory employee in the early 1970’s, you have satisfied my OCD fascination about Rickenbacker production details and I look forward to the next article!